Student Project: Medical Product Design - A device for removing anesthetic waste gases

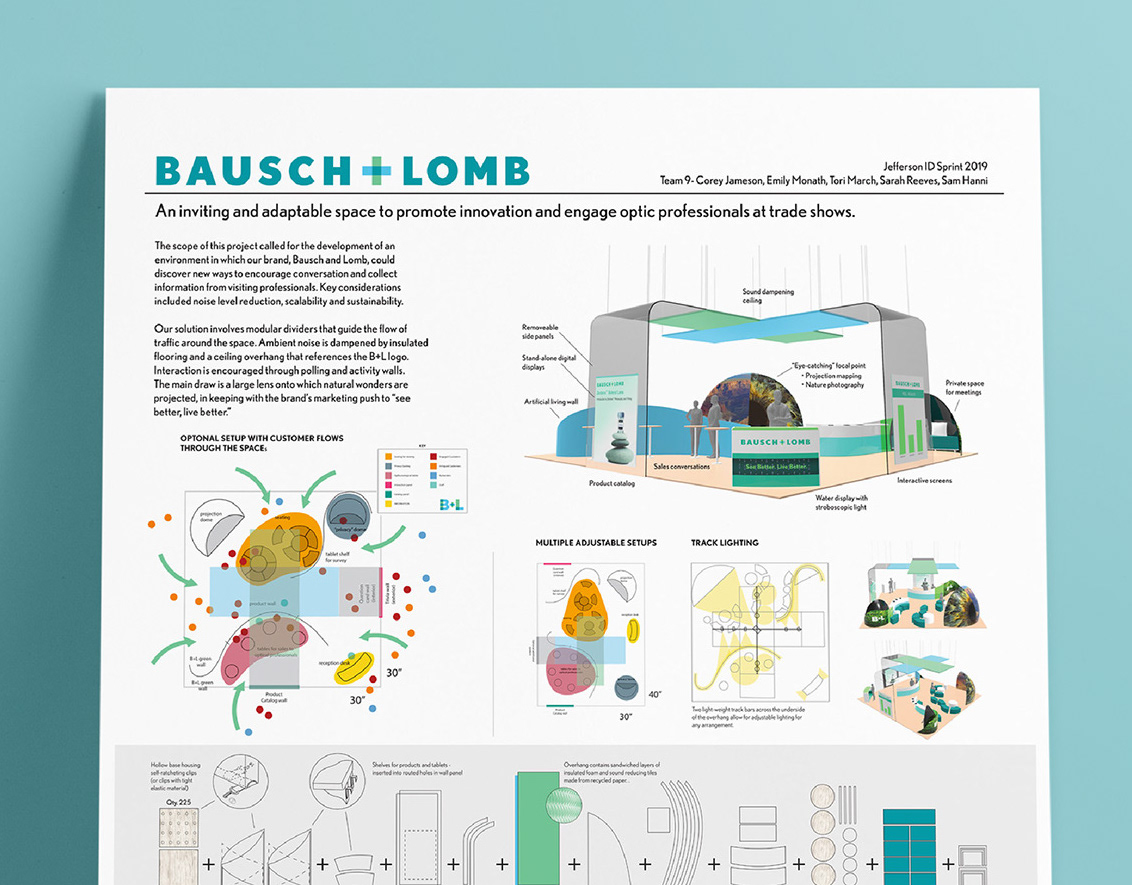

Part of a summer fellowship with the Thomas Jefferson Health Design Lab and Bressler Group

Team: Cary Hess - M.D. Candidate '22, Corey Jameson - M.S. Industrial Design '20, Alice Karp - M.D. Candidate '23, Delara Kiani - M.S. Industrial Design '20

Design Category: Industrial Design, Graphic Design

My Role: Project Manager, Research & Development, Prototyping & Ideation, Illustrations and Graphics (including infographics, storyboards and brand design), Pitch Presentation Design

Tools: Photoshop, Illustrator, Indesign, Procreate, Physical prototypes, Keyshot

*This product is patent protected.

The Consequences of Chronic Exposure to Anesthetics

Anesthesiologists are exposed to anesthetic gases well over recommended daily limits, leading to a number of health concerns, including increased risk of miscarriages, birth defects, fertility issues, cancer and CNS depression. These risks are not limited to first degree exposed persons, but extend to members of their household as well.

Our team of two industrial design students and two medical students worked to find ways to reduce these harmful impacts of chronic exposure to waste anesthetic gases. To begin our process, we conducted a white paper study on this issue.

I condensed our findings into this infographic below to highlight the key points from our research.

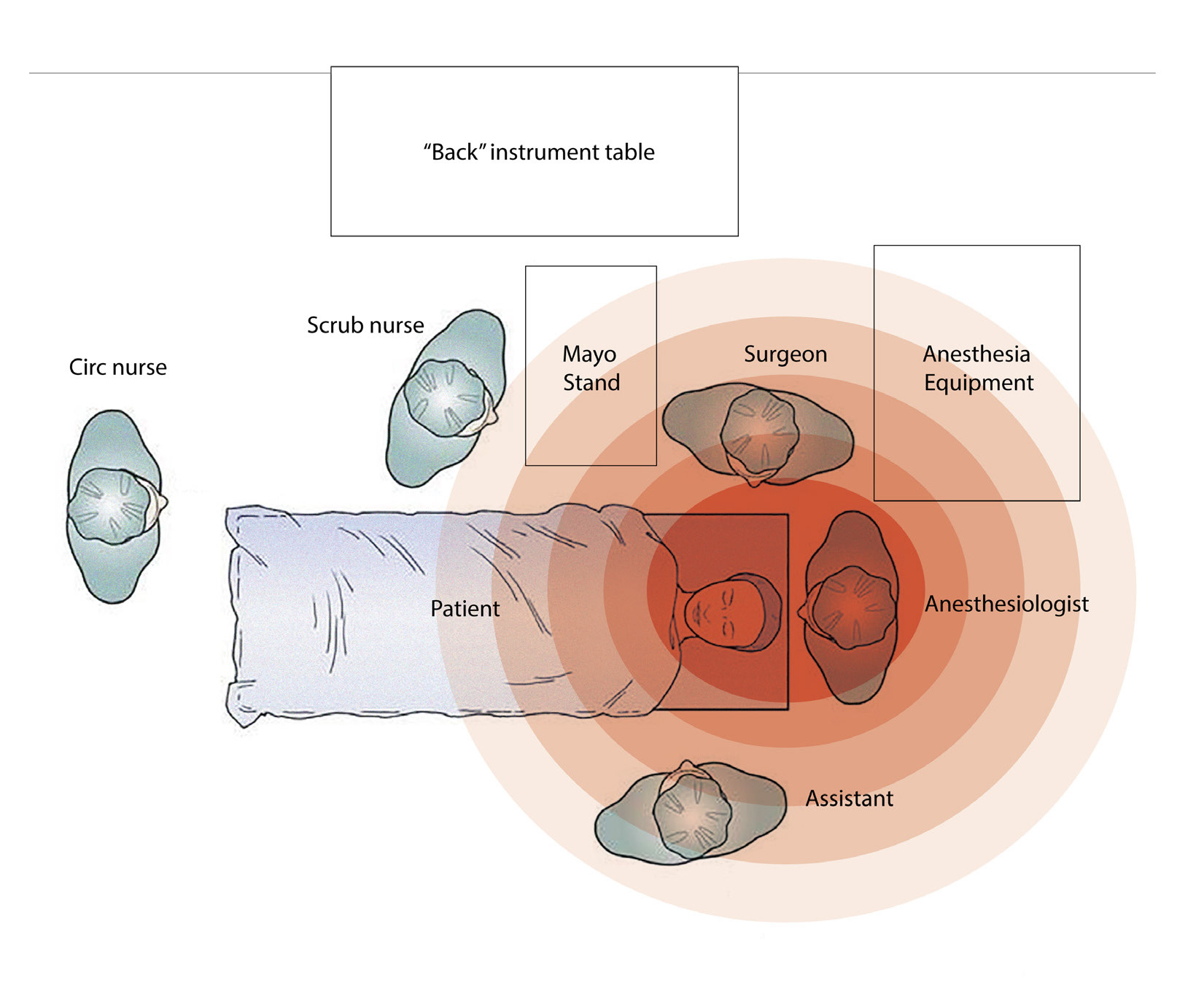

Concentrations of Gas in the Operating Room

OSHA sets maximum allowed exposure limits for anesthetic gases at 2ppm. Workplaces are required to meet that standard in order to fall within federal guidelines. However, testing is typically performed once a month and measured at a single point within the operating room. While that measurement may come back as less than 2ppm, data collected in a 1999 study showed that airborne concentrations of anesthetic gases vary dramatically within the operating suite.

We conducted our own study using badges that measure anesthetic gases, developed by Assay Technologies. We had anesthesiologists wear these badges while on shift. Our results showed readings 5.5x the OSHA recommended levels.

Gas Leakage

We identified several areas where anesthetic gases were spilled into the OR. The most actionable area for possible solutions surrounded the anesthetic mask.

Our Solution

Respiro is a flexible outer shell that fits over any size anesthetic mask. The shell traps the anesthetic gases and internal tubing suctions those gases away, preventing them from spilling into the operating room environment. The device is designed to be disposed with the rest of the anesthetic equipment used for each patient.

*This product is patent protected.

A Glimpse into the Product Journey

PROTOTYPE TIMELINE:

SKETCHES, MOCKUPS, AND PHOTOGRAPHS

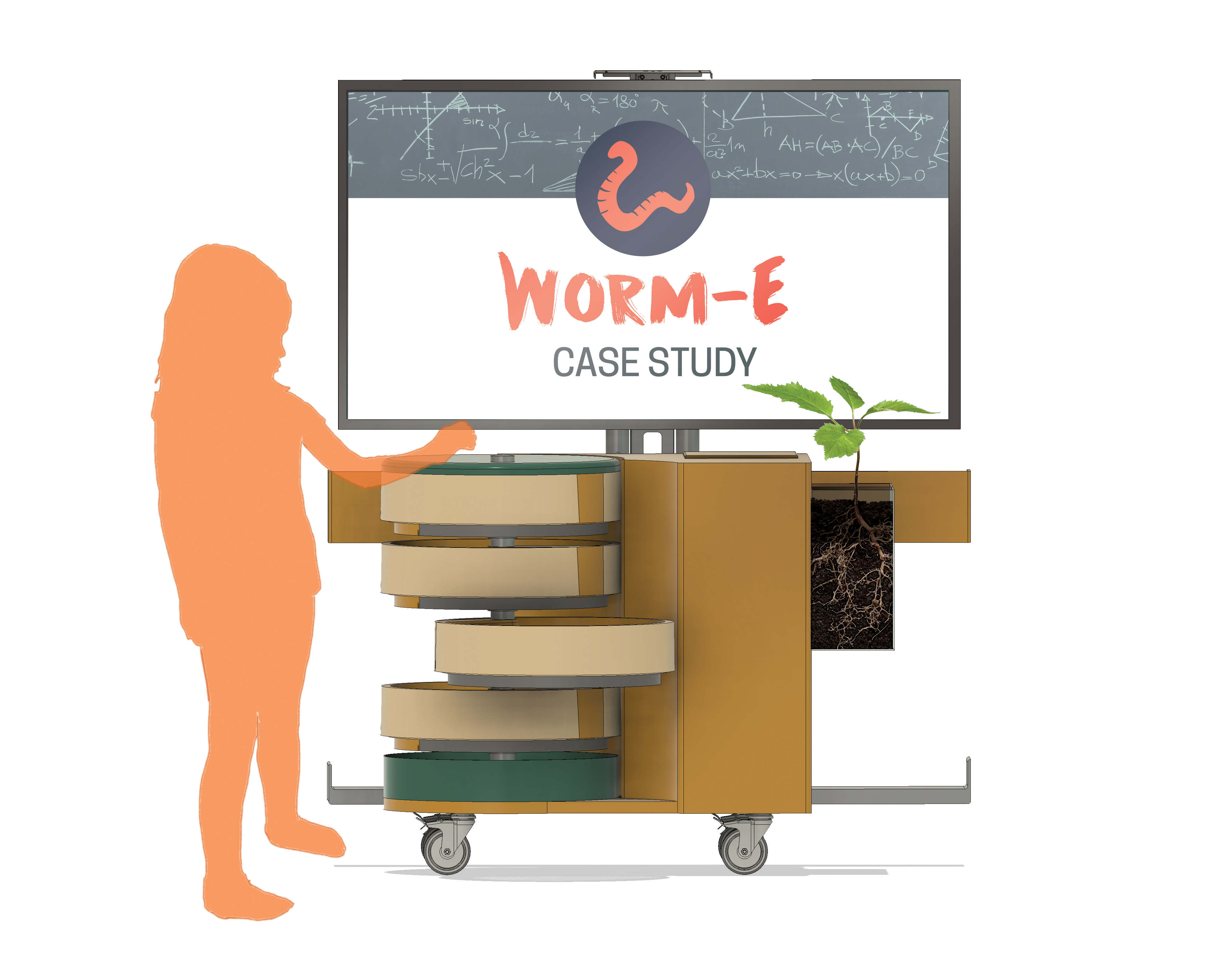

Product Use

I illustrated this storyboard to explain how our product would be set up and used for each anesthetic procedure. This storyboard proved an imperative part of our pitch presentation, giving our audience an understanding of how we envisioned Respiro in action.

The Final Product in Action

Special thanks to staff from the Bressler Group for guidance and support on this project. They helped us create the silicone mold used as the outer shell. Delara Kiani created the final CAD model for the inner tubing that was printed

at the Jefferson Health Design Lab using a 3d printer.

at the Jefferson Health Design Lab using a 3d printer.